[ad_1]

A mix of provide chain chaos, greater prices and issues about working situations is forcing some western vogue manufacturers to rethink their decades-old dependence on factories in China.

Dieter Holzer, the previous chief government and a board member of Marc O’Polo, mentioned the Swedish-German vogue model began to swap some suppliers within the nation in favour of factories in Turkey and Portugal in 2021.

The choice was meant to “stability and take out danger out of your provide chain and make it extra sustainable”, he mentioned. “I feel many firms throughout the business are reviewing their publicity [to China].”

The shift away from mass textile manufacturing within the nation, albeit nonetheless in its early phases, marks the reversal of years of outsourcing to a area that has come to dominate the textile supply chain.

Huge names akin to Mango and Dr Martens have not too long ago minimize or signalled their intention to shift manufacturing out of China or south-east Asia.

“The massive message is decreasing reliance on China,” Dr Martens’ chief government Kenny Wilson mentioned in November. “You don’t need all your eggs in a single basket.”

The bootmaker has moved 55 per cent of its complete manufacturing in another country since he took over in 2018. Simply 12 per cent of its manufacturing for the 2022 autumn/winter assortment was manufactured in China in contrast with 27 per cent in 2020 and it estimated it will drop to five per cent this 12 months.

“We’re being deafened by the sound of garments producers [moving] away from Asia,” mentioned Rosey Hurst, director of moral enterprise consultancy Impactt.

The relocation was additionally being pushed by stricter legal guidelines being launched within the US and Europe towards labour abuses, she added, following the alleged use of compelled labour within the cotton-rich territory of Xinjiang in China.

Mango’s chief government Toni Ruiz mentioned in December he was contemplating shopping for much less from China “however we’ll be very alert to how issues evolve”.

“What we’re is the extent to which all this world sourcing, developed over a few years, may change into extra native,” he mentioned.

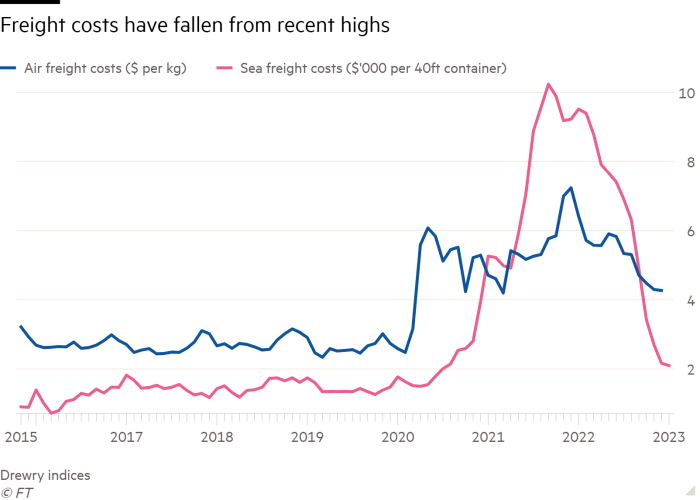

The shift was accelerated by continued provide chain disruption for the reason that onset of the Covid-19 pandemic, which led to a bounce in freight prices, in addition to vital shipping delays as manufacturing unit employees at manufacturing hubs throughout Asia fell ailing or have been compelled to isolate.

One business marketing consultant mentioned that one retail consumer’s ski put on, from a earlier season, arrived in the summertime of 2022.

“For a lot of, gone are the times of producing solely in China and transport in every single place,” mentioned Todd Simms, vice-president at provide chain intelligence platform FourKites.

“Disruptions have elevated prices to ship completed items, making it simpler to justify operations in new international locations in alternate for extra resilience,” he added.

The monetary incentives to stay within the area are diminishing as wages go up after years of low cost labour — a significant draw for a lot of family names to outsource manufacturing to far-flung locations.

Based on statistics from China’s Nationwide Bureau of Statistics, the typical manufacturing unit wage doubled between 2013 and 2021, from Rmb46,000 ($6,689) per 12 months to Rmb92,000.

Jose Calamonte, chief government of on-line vogue retailer Asos, informed traders on the firm’s full-year outcomes presentation final 12 months that merchandise manufactured in China weren’t as aggressive as they appeared relative to Europe, as soon as transport and transport prices have been taken into consideration.

“We strive to consider the ultimate [profit] margin as soon as we’ve made the ultimate sale,” he mentioned.

European clothes retailers’ efforts to chop supply instances, as vogue developments and shopper wants change shortly, is another excuse behind their choice to go for suppliers nearer to residence.

“We’ve been taking management of our manufacturing,” mentioned a spokesman for a British luxurious model, including that the business has been consolidating in Europe for years now. “This has been a pattern for causes to do with pace and effectivity.”

Plans to shift manufacturing away from Asian garment hubs, nevertheless, aren’t that superior owing to their complexity. International locations akin to China and Vietnam symbolize the lion’s share of textile exports, in keeping with 2020 information from CEPII.

For instance, greater than half of suppliers to Inditex, the world’s largest vogue retailer, have been based mostly in Asia in 2021, solely a marginal discount on 2018.

Turkey has been positioning itself as a winner from western manufacturers transferring their manufacturing, not least as a result of it’s a part of the EU customs union, permitting frictionless commerce between member states.

“It’s a common vacation spot and already utilized by the likes of Hugo Boss, Adidas, Nike, Zara,” mentioned Simon Geale, government vice-president of procurement at provide chain consultancy Proxima.

An more and more essential consideration for retailers is traceability within the provide chain after years of broadly reported labour abuses.

“[Because of US laws against cotton from Xinjiang], manufacturers need to have significantly better traceability, ” mentioned Impactt’s Hurst.

“Then we’ve got obtained European legal guidelines [on forced labour] developing. It’s placing stress on the business to get a grip,” she mentioned.

However she warned: “There isn’t sufficient cash in [international supply chains] to run issues the way in which they need to be carried out. [Given the current economic crisis], that’s solely going to worsen.”

Maximilian Albrecht, an analyst at AlixPartners, mentioned that many quick vogue labels have been additionally abandoning China so as to differentiate themselves from Shein, the quickly rising Chinese language quick vogue large.

“European manufacturers can’t match Shein on their prices of manufacturing, their community of manufacturing, their relationships,” Albrecht mentioned.

“I feel you’ll see some manufacturers say ‘properly, we are able to’t match that so we’ll transfer to Europe’. You possibly can nonetheless promote the story that they’ve greater high quality merchandise. Whether or not that’s truly true is one other factor.”

[ad_2]

Source link